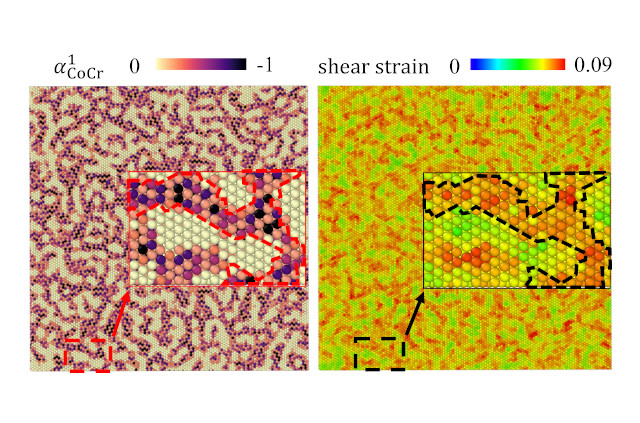

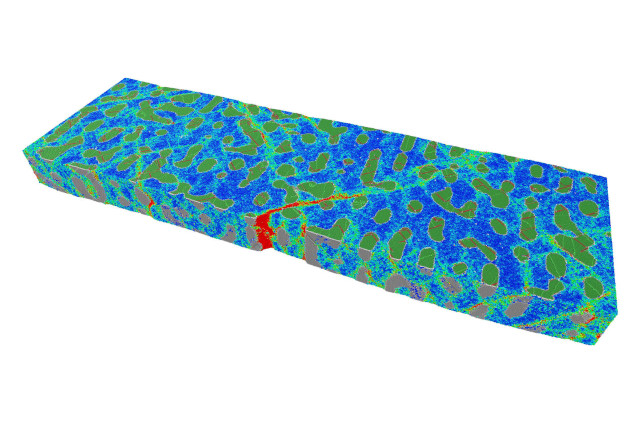

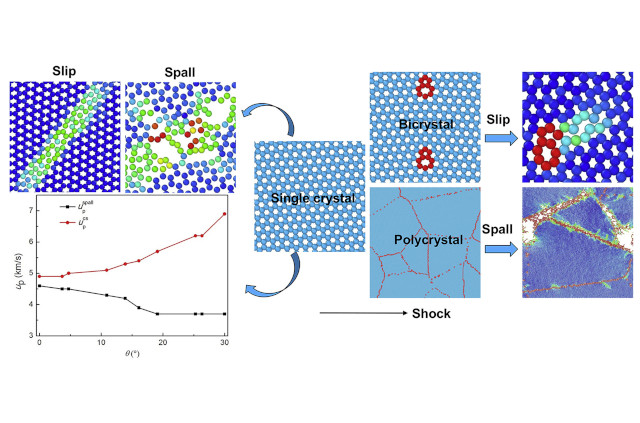

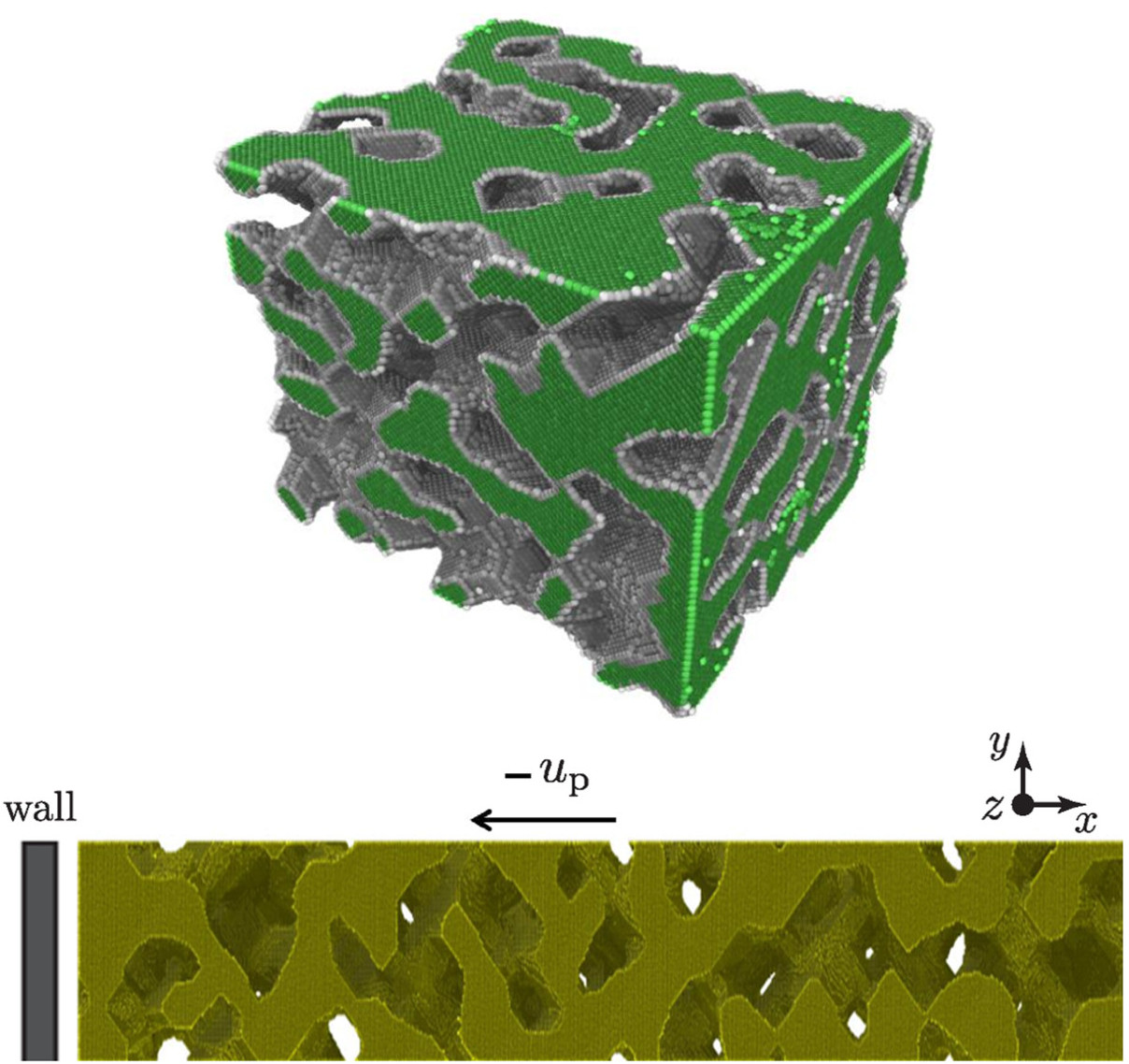

As the numbers of medium- to high-entropy alloys being studied and impressive structural properties they exhibit increase rapidly, questions regarding the role played by their complex chemical fluctuations rise concomitantly. Here, using a combination of large-scale molecular dynamics (MD), a hybrid MD and Monte-Carlo simulation method, and crystal defect analysis, we investigate the role lattice distortion (LD) and chemical short-range order (CSRO) play in the nucleation and evolution of dislocations and nanotwins with straining in single crystal and nanocrystalline CoCrNi, a medium entropy alloy (MEA). LD and CSRO effects are elucidated by comparisons with responses from a hypothetical pure A-atom alloy, which bears the same bulk properties of the nominal MEA but no LD and no CSRO. The analysis reveals that yield strengths are determined by the strain to nucleate Shockley partial dislocations, and LD lowers this strain, while higher degrees of CSRO increase it. We show that while these partials prefer to nucleate in the CoCr clusters, regardless of their size, they find it increasingly difficult to propagate away from these sites as the level of CSRO increases. After yield, nanotwin nucleation occurs via reactions of mobile Shockley partials and is promoted in MEAs, due to the enhanced glide resistance resulting from LD and CSRO.

(Acta Materialia 199, (2020) 352-369)